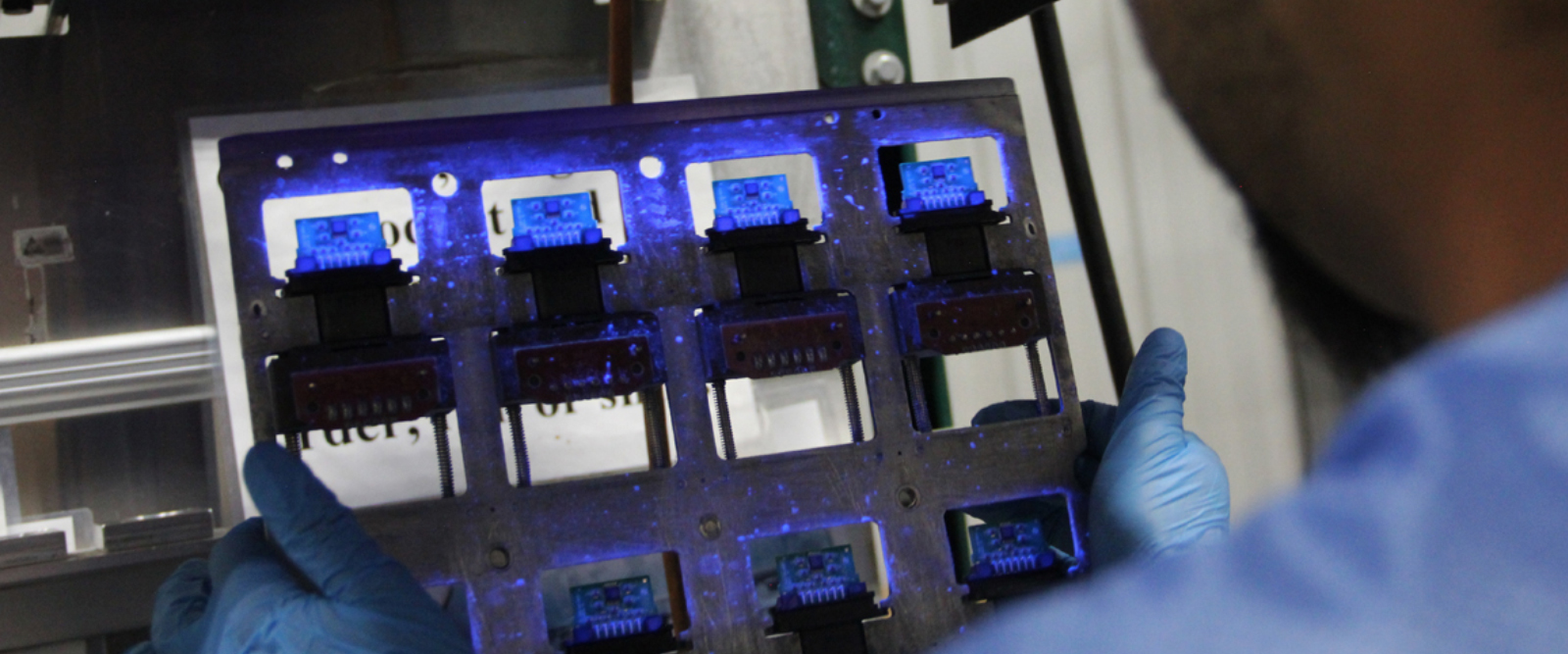

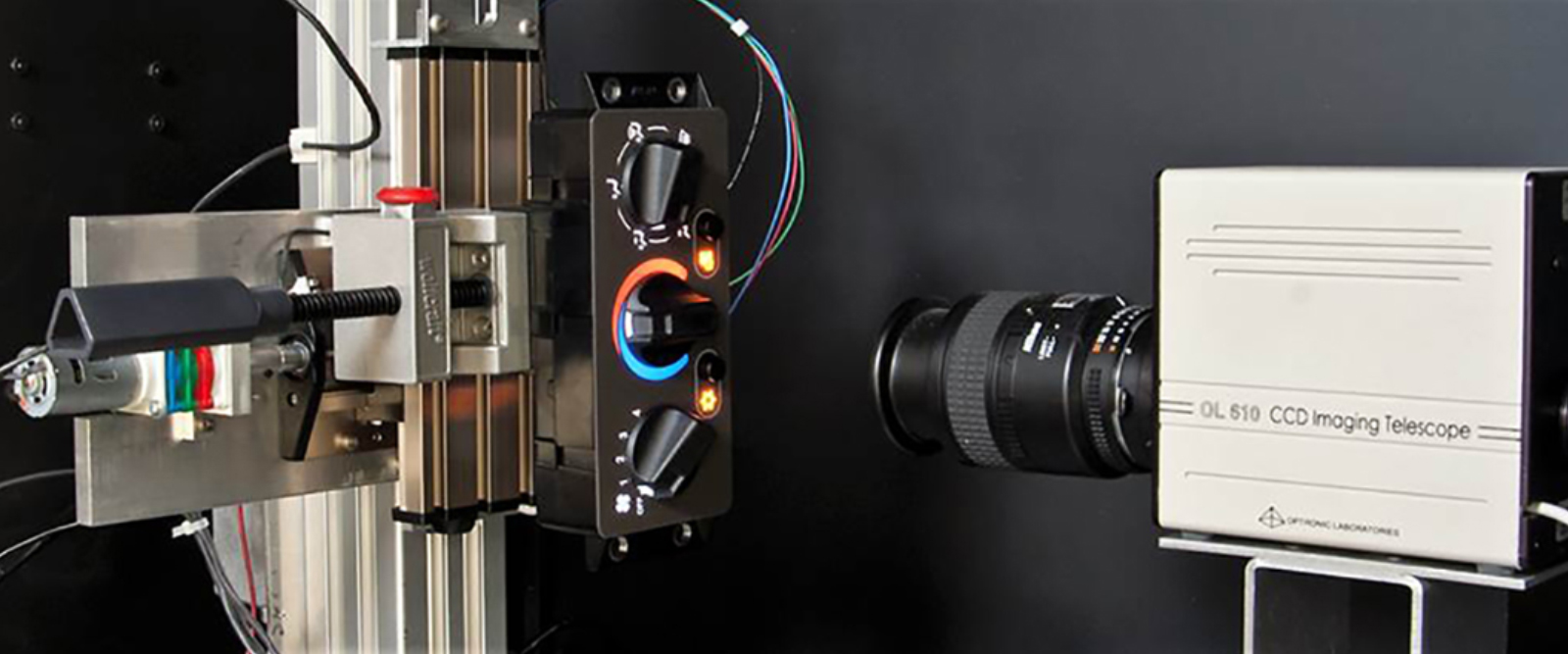

Indak has extensive test laboratory equipment and procedures for testing product performance. We can test for many environments and conditions to ensure each product meets or exceeds customer expectations. Throughout the various stages of prototype development, the Indak Design Engineering team will have prototype parts fabricated for reliability, environmental and durability testing.

Indak test laboratories have extensive equipment for testing in a wide variety of environments and conditions experienced in the Automotive, Outdoor Power, Medical, Healthcare, and Consumer Electronics industries.